Mechanical Checking Center: Evaluating Material Performance

Are you interested concerning how materials are evaluated for their efficiency in design? Look no more! In this article, we will explore the value of product screening as well as the numerous mechanical examinations utilized to assess product performance. You will gain an understanding of the equipment and techniques employed in these tests, as well as how to interpret and also analyze the outcomes. Obtain all set to explore the globe of mechanical testing and enhance your knowledge of product residential properties!

Significance of Material Screening in Engineering

You need to recognize the value of material screening in design to guarantee the performance and also dependability of your products. Product testing is an essential action in the layout as well as manufacturing procedure. By subjecting materials to numerous examinations, you can assess their mechanical residential or commercial properties and figure out if they satisfy the required requirements as well as specifications.

Product testing also allows you to make sure the dependability and durability of your items. By imitating real-life problems and also subjecting products to severe temperature levels, moisture, and also harsh settings, you can analyze their resilience and performance in time. This helps you make informed decisions about the materials you pick for your items, staying clear of possible failings as well as costly recalls in the future.

In addition, material screening gives valuable data that can be utilized to enhance the design as well as manufacturing process. By assessing the outcomes of different tests, you can maximize the product choice, identify locations for renovation, as well as enhance the total high quality of your products.

Sorts Of Mechanical Tests for Evaluating Product Performance

When it comes to examining material performance, there are numerous kinds of mechanical examinations that can be performed. One usual test is the tensile test, which gauges the stamina and ductility of a product by applying stress up until it breaks. An additional test is the compression test, which reviews a material's capacity to stand up to compressive forces.

Recognizing Material Characteristic for Screening

When you are assessing product efficiency in a mechanical testing facility, it this hyperlink is crucial to have a thorough understanding of the various homes that can influence the product's behavior. Strength is normally gauged via tests such as tension or compression tests, where the product is subjected to drawing or pressing pressures till it reaches its breaking point.

One more crucial building is solidity, which describes the material's resistance to indentation or scratching. This residential property is critical in determining the material's ability to withstand damage. Hardness can be determined utilizing different techniques, including the Brinell or Rockwell firmness tests.

Furthermore, it is necessary to think about the material's ductility, which is its capability to go through plastic contortion without fracturing. Ductility is determined with tests like the tensile test, where the material is stretched until it reaches its snapping point. This home is especially crucial in applications where the material needs to be bent or formed without breaking.

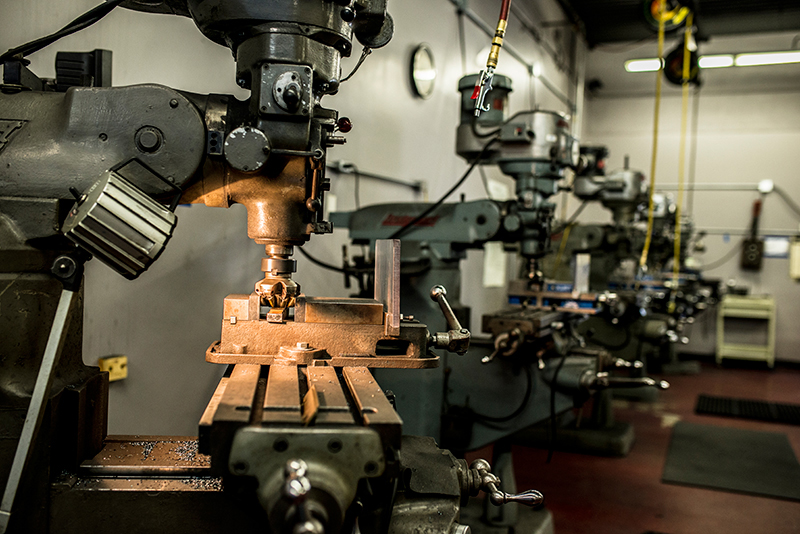

Tools and also Strategies Made Use Of in Mechanical Examining

To properly examine the buildings of various materials, it's important to acquaint on your own with you can try these out the devices and also strategies utilized in mechanical screening. One of the most generally utilized tools is the universal testing maker. This device uses regulated forces to check the strength, flexibility, as well as various other mechanical buildings of materials. It includes a tons frame, holds, and a control board. By adjusting the grasps and establishing the desired pressure, you can test different samplings. One more vital tool is the hardness tester, which gauges the resistance of a material to imprint. There are various sorts of solidity testers, such as Rockwell, Brinell, and Vickers, each utilizing a various technique to establish hardness. In enhancement to these equipments, there are various methods made use of in mechanical testing. Tensile screening, for instance, involves stretching a product until it breaks to determine its toughness and elasticity. Compression screening, on the various other hand, involves applying forces that press the product to measure its stamina as well as security. By understanding the equipment as well as methods made use of in mechanical testing, you can efficiently examine the efficiency of various products.

Interpreting and also Studying Examination Results for Material Performance Evaluation

When interpreting and assessing examination results, you'll require to meticulously take a look at the data to determine just how well the materials perform. These can suggest potential concerns or variances in the material's efficiency.

Next off, consider the certain residential or commercial properties being examined and contrast them to the wanted specifications or criteria. This could include exploring the testing approach, example prep work, or even the material itself.

Final thought

So there you have it, comprehending the significance of material testing in engineering is crucial for evaluating material efficiency. By carrying out different mechanical tests, you can gain valuable understandings right into the homes as well as behavior of various products. With the best equipment and also methods, you can precisely measure and also examine test see this site outcomes to analyze material performance. So make certain to prioritize material screening in your engineering tasks to make sure optimal efficiency as well as reliability.